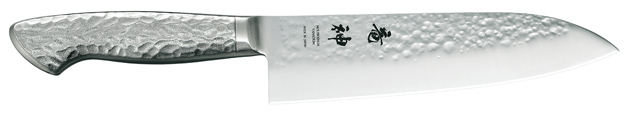

Origin of Ryujin Brand

Owner and creator of Ryujin, Shosaku Motomiya sought a brand for his kitchen knives originating from Tsubame, the city where he was born and raised in Niigata Prefecture. He considered a name associated with Iyahiko Jinja, a historical shrine of Tsubame known affectionately by the locals as “Oyahiko-Sama.”

Ame-no-Kaguyama-no-Mikoto, the enshrined god at Iyahiko Jinja is the grandson of Amaterasu-Omikami, the sun goddess. In the past when Ame-no-Kaguyama-no-Mikoto came down from the heavens and resided in Kumano, in the southeastern part of the Kii Peninsula, Emperor Jinmu and the imperial warriors fell into a deep sleep from venomous mist issued by the enemy. Through a dream, Ame-no-Kaguyama-no-Mikoto was ordered by higher gods to bestow the Futsu-no-Mitama-no-Mitsurugi, a mystical sword, to Emperor Jinmu. This powerful sword previously enabled subjugation of the nation by Take-Michizuka, the god of thunder, and on this occasion awoke Emperor Jinmu and his retinue, who promptly defeated the enemy. Emperor Jinmu continued to campaign successfully against many adversaries and reached Yamato, where he was crowned the nation’s first emperor at Kashiharanomiya.

The sword Futsu-no-Mitama-no-Mitsurugi represented the source of the soul for the kitchen knife Shosaku Motomiya wanted to create, but the name was too long for a brand. Legends speak of Emperor Jinmu having dragon scales on his body, while the Emperor’s daughter Tamayorihime was a god of the seas. The soul of Emperor Jinmu’s sword, therefore, is the heritage to the brand name “dragon god,” or in Japanese, Ryujin. The master’s creations under the brand name Ryujin relate the soul of the sword Futsu-no-Mitama-no-Mitsurugi.